Overhead Conveyors

All-Flex Conveyors

Unibilt Enclosed Track Conveyors

Monoveyors 8000 Series

Power and Free 8500 Series

Monoveyors – 1500 & 2000 Series

Product Brochures

All Flex Conveyors

8000 Series Monorails

Power and Free 8500 Series

Monoveyors 1500 & 2000 Series

Unibilt Enclosed Track Conveyors

Unibilt Enclosed Track Conveyors

Unibilt conveyors by Jervis B. Webb are ideal for light to medium-duty material handling applications. Engineered for reliability, flexibility, and clean operation, the Unibilt system uses pre-engineered modular components and a universal link chain that allows for tighter radius curves and versatile routing in limited spaces. The enclosed track design protects the chain from contaminants, reduces maintenance, and improves workplace cleanliness. Available in hand-push, overhead power & free, and inverted configurations, Unibilt supports single product loads up to 250 lbs and integrates easily into assembly, processing, painting, and storage operations across diverse industries.

Features and Benefits:

- Modular Enclosed Track System

Precision-formed Webballoy® track offers high strength, uniformity, and reduced wear for longer service life. - Flexible Routing in Tight Spaces

Universal link chain enables tighter 24″ radius curves and vertical transitions with reduced clearance needs. - Clean and Contained Operation

Enclosed track design isolates chain and bearings from external contamination; ideal for paint, wash, and food zones. - Quiet, Low-Maintenance Drives

One-piece caterpillar drives deliver smooth, efficient motion with overload protection and minimal noise. - High Load Capacity

Supports up to 125 lbs per load wheel assembly and 250 lbs on 4-wheel chain attachments. - Reliable Chain Performance

Heat-treated forged pins and hardened guide/load wheels rated to 10,000 lb ultimate strength for rugged durability. - Ease of Installation and Modification

Nested yoke connections simplify assembly, while modular design supports fast expansion or reconfiguration. - Compact, Low-Profile Design

Conserves headroom while offering visually clean, efficient overhead material handling. - Proven Across Diverse Applications

Suitable for manufacturing, assembly, painting, warehousing, processing, and more.

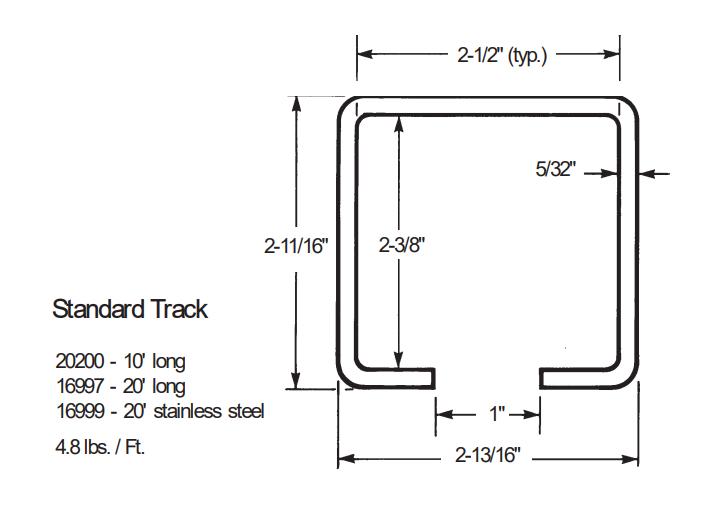

ENCLOSED TRACK:

Straight Track is made of UnibiIt Webballoy – a near-square, tubular section 2-13/16″ wide x 2-11/16″ high with a 1″ slot. Track is composed of low-alloy, high-strength, fine-grained 5/32″ thick steel, which is formed for uniformity to + 1/32″ tolerance; minimum 45,000 P.S.I. yield strength and 60,000 P.S.I. minimum ultimate strength.

CHAIN PULL:

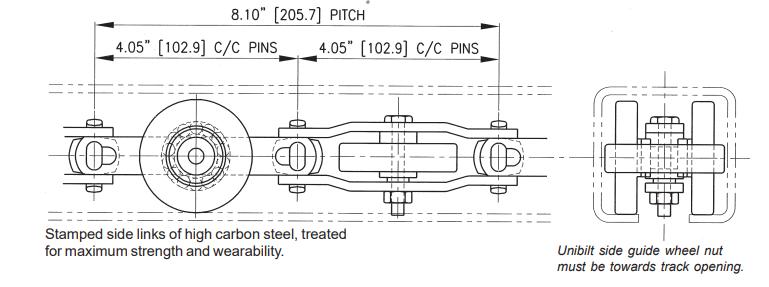

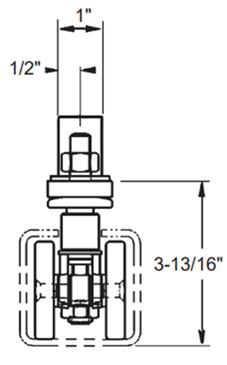

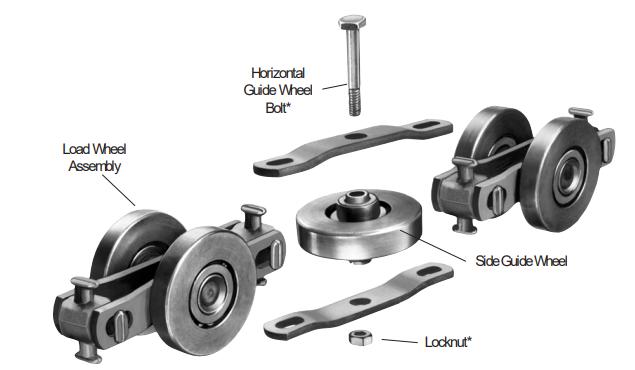

GUIDE WHEEL LINK:

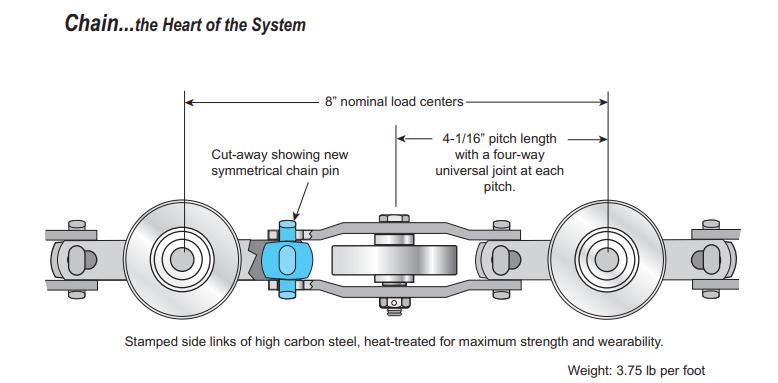

CHAIN ASSEMBLY:

The ultimate strength of the Unibilt 27826 chain is 10,000 pounds minimum, providing a safety factor of more than 16:1 when subjected to the recommended maximum chain pull of 600 pounds. Chain growth, under ideal test conditions at a maximum 550 pounds of chain pull, Generated 1″ of elongation in a 100-foot strand over a one-year test period.

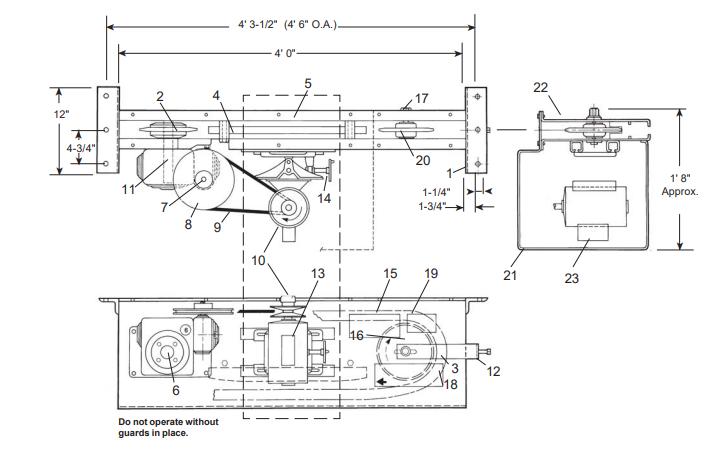

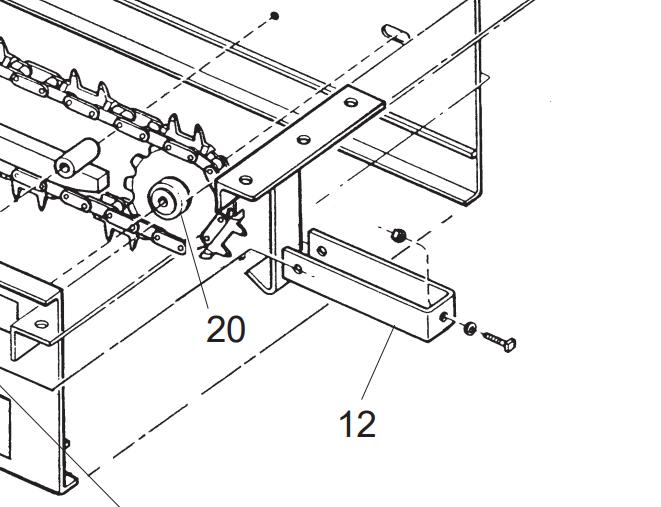

CATERPILLAR DRIVE:

Unibilt 300 lb. Capacity Drives (Left hand standard) Constant Speed, Variable Speed, and VFD All 300 lb. constant and variable speed drives are identical with the following exceptions: Constant Speed Drive: Shipped with motor and Constant Speed Motor Pulley. Variable Speed Drive: Shipped with motor, tilting motor base and Variable Speed Motor Pulley. VFD Controlled Drive: Shipped with Constant Speed Pulley. AC motor and controller are shipped separately from vendor.

CATERPILLAR DRIVE:

OVERLOAD PROTECTION:

The 300-pound series drives are protected by a torque limiter *(friction disc) device mounted integral with the caterpillar chain drive sprocket and shaft. This method replaces the torque arm controlled firing (triggering) of a power shut-down limit switch that is standard on our 600-pound drives. The intent is to provide enough controlled pressure (squeeze) upon both machined faces of the otherwise unconnected sprocket to cause it to rotate and drive the caterpillar chain. At the same time, the factory-adjusted torque (pressure), calibrated in foot/pounds, is such that a conveyor chain jam or overload condition will overcome the pressure applied. When converted to chain pull, this pressure provides a 450-pound (300-pound x 1.25%) overload safety factor.

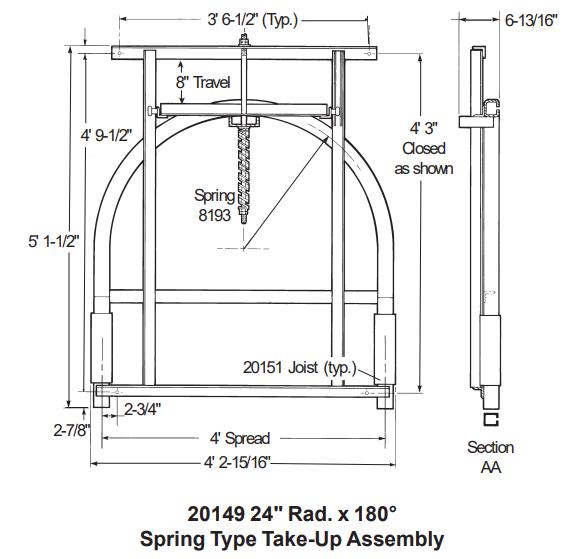

TAKE-UP:

A conveyor take-up, sometimes called a slack chain adjuster, is required in Unibilt conveyor systems to control and eliminate any slack chain that may accumulate in the system. A take-up compensates for chain growth resulting from chain wear and for chain expansion or contraction due to temperature changes, which result from outdoor atmosphere or from bake ovens.

Collapsing the take-up to its shortest length facilitates connecting or disconnecting the conveyor chain while it is threaded into or removed from the track. When the chain is reconnected, the take-up should expand until the proper chain tension results. One way to collapse a spring take-up is to use a come-along or similar device. While the unit expands to its normal position, extend the come-along carefully.

SPROCKET TAKE-UPS:

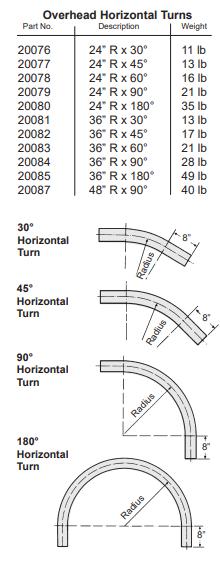

HORIZONTAL TRACK TURNS:

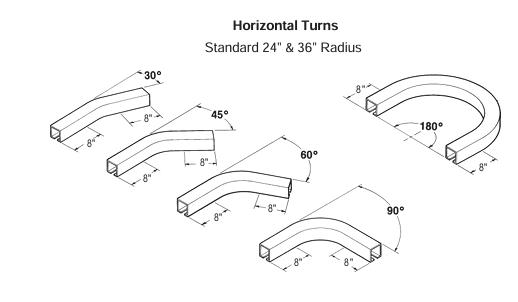

All horizontal turns are available in 24” and 36” radii and vertical curves illustrated are carried in stock for immediate delivery. However, special radius and/or degree turns can be fabricated upon request. For smaller than 24” radius, horizontal traction wheels can be furnished.

HORIZONTAL TRACK CURVES:

HORIZONTAL CURVE SIZES:

Turns and curves in all powered systems shall be restricted to a minimum of 24″ radius, thereby assuring lower chain tensions and longer chain life. As an added feature to ensure longer turn and curve life, all 24″ and 36″ radius units are flame-hardened on the wear surfaces after forming.

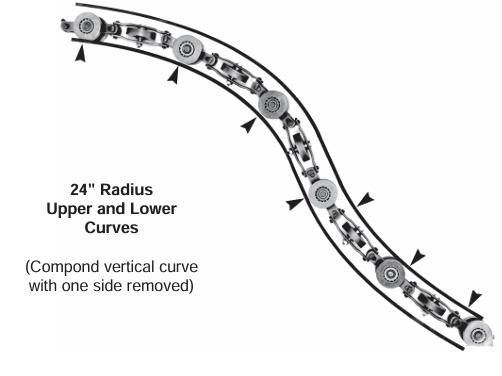

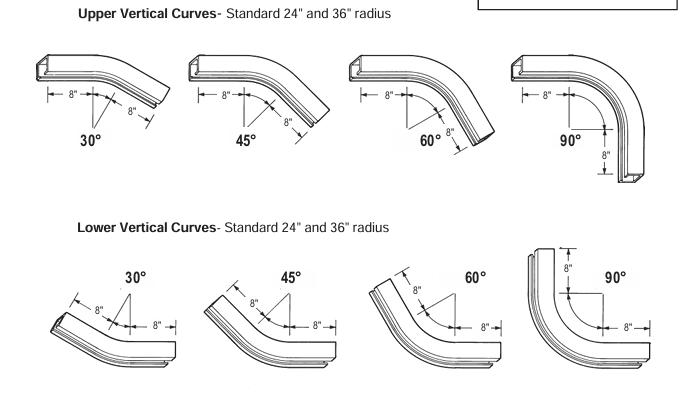

VERTICAL TRACK TURNS:

VERTICAL CURVES:

All horizontal turns are available in 24” and 36” radii and vertical curves illustrated are carried in stock for immediate delivery. However, special radius and/or degree turns can be fabricated upon request. For smaller than 24” radius, horizontal traction wheels can be furnished. Both horizontal turns and vertical curves are formed from 20200 track. Horizontal turns 24” and 36” radius and vertical curves 24” radius are heat-treated in areas of wheel contact to ensure a hard, tough surface for added anti-wear qualities. Standard turns are fabricated with 8 inches of straight track on each end. However, special turns can be fabricated to order with less for areas where turn tangents are closer than 16 inches.

24” radius and 36” radius horizontal turns and vertical curves are heat treated on the wear surfaces for added anti-wear qualities.

Vertical curves – have a minimum of 36″ radius and a maximum 45 degree of incline & decline. The factory should be consulted for inclines or declines requiring an angle greater than 45°

VERTICAL BEND SIZES:

Product Gallery

SRS Conveyors manufacturer of the All-Flex Enclosed Track Conveyors are designed and built on the principles of increasing productivity, reliability, flexibility and simple installations.

Our team of engineers can find the

solutions that is right for you.