Auto Uniform Conveyors

Product Brochures

S-700 Catalogue

Garment Conveyor Catalogue

All Flex Conveyors

Auto Uniform Conveyors S-700

SRS Auto Uniform Conveyor S-700 simplifies employee uniforms and locker bag handling. Used in hotels, casinos, hospitals and correctional facilities it’s design benefits are to eliminate space wasting metal lockers and uniform attendants. The employee simply swipes or enters their employee ID number enabling SRS Auto Uniform Conveyor S-700 to automatically retrieve their pre assigned uniform/locker bag. Once the employee has changed or completed their shift, the employee simply re-swipes or enter the employee ID number and there pre-assigned designated slot will present itself for the employee to return the uniform/locker bag. The loading of the clean uniforms are performed by an attendant who scans the barcode or RFID chip allowing the conveyor to automatically advance to that employees dedicated spot for loading. The flow of this operation is all managed by our Auto Uniform S-700 software that also tracks daily activities, inventory, cleaning, purchasing, selling and repairs/alterations of uniforms.

Features

- 24hr uniform retrieval system

- Uniform attendant no longer required

- Eliminates costly locker room space

- Increases productivity

- Flexible modular design

- Maximum space utilization

- Optional enclosed or open track design

- Caterpillar or sprocket drive options

- Standard inverter controlled drive

- Heavy duty long lasting components

- Used with barcode, RFID chip or man-readable labels

- System activated by ID card, no attendant needed

- Integrate with Uniform Management Software

- Manual ID number option to access uniform

- Return on investment 18 months or less

Auto Uniform Conveyors S-700: Features

Access Scanning:

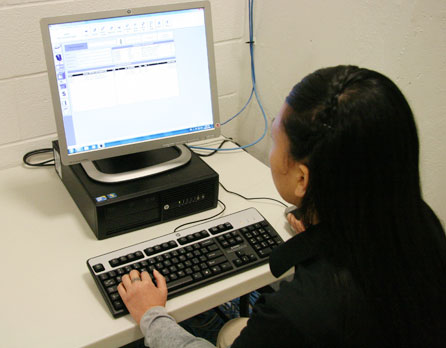

SRS Auto-Uniform Conveyor S-700 offers the latest technology for advanced management of uniforms and locker bags. The employee can be recognized by imbedded smart chip ID cards, bar code, magnetic strip, finger print or keypad entry.

![]()

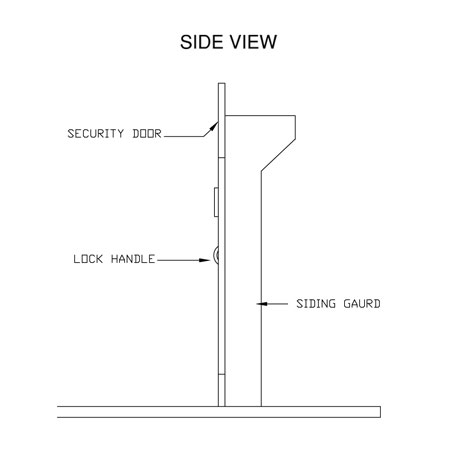

Access Door:

Once identification of the employee has been recognized with our S-700 Uniform Management Software, the Auto-Uniform S-700 Conveyor automatically rotates to delivery their locker bag/uniform. The employee simply opens the timed out security door to retrieve their items. Once the items have been retrieved, the security door will automatically lock behind them for the next employee to use. Garments that are equipped with RFID chips can also be tracked through our access door scanner (optional) and throughout the laundering operation.

![]()

Security:

SRS Auto-Uniform Conveyor S-700 helps prevent property loss due to employee misplacement or theft by preventing un-authorized access to the locker bags/uniforms. This is accomplished by our commercially rated aluminum/Lexan access door complete with solenoid activated locks and door status sensors. In addition employees operating the security door are also prevented from accessing neighboring locker bags/uniforms with SRS S-700 unique locker bag/uniform lock out clamps.

![]()

Return Chute:

With SRS’s return chute soiled uniforms can be dropped off at any time. Uniforms with RFID chips can also be tracked with our optional chute scanner that records all soiled uniforms returned. For bar coded uniforms a fixed scanner is provided for employees to scan prior to dropping uniforms into the chute.

![]()

![]()

Loading Clean Uniforms:

The uniform attendant has the option of re-loading clean uniforms at any time. The attendant simply scans the uniform’s RFID chip or barcode activating the S-700 conveyor controller to automatically rotate taking the shortest route to that employee’s dedicated slot for hanging. These steps are then repeated until all uniforms are loaded onto the conveyor. In the event that an employee wishes to access their locker bag, the S-700 in use light will flash indicating to the uniform attendant that an employee is activating the system to retrieve their locker bag. The uniform attendant will be locked out until the employee has retrieved their locker bag.

Uniform Software:

The Auto Uniform S-700 management software offers a wide variety of data tracking for the uniform department. For example.

- Keeps track of and assures correct uniforms are available for employees

- Makes sure all garments have been returned for cleaning or as a result of termination

- Automatically assigns loaner garments and assures there return at the end of the shift

- Automatically audits cleaning/laundry bills and allocates uniform and laundry expenses to each department

- Maintains the repair and wear history of all uniforms

- Provides full inventory control of all uniforms

The Auto Uniform S-700 can also interface with your existing uniform management software or interface with industries standard inventory software.

![]()

Benefit Summary:

- 24hr uniform retrieval system

- Uniform attendant no longer required

- Eliminates costly locker room space

- Increases productivity

- Flexible modular design

- Maximum space utilization

- Optional enclosed or open track design

- Caterpillar or sprocket drive options

- Standard inverter controlled drive

- Heavy duty long lasting components

- Used with barcode, RFID chip or man-readable labels

- System activated by ID card, no attendant needed

- Integrate with Uniform Management Software

- Manual ID number option to access uniform

- Return on investment 18 months or less

Auto Uniform Conveyors S-700: Specifications

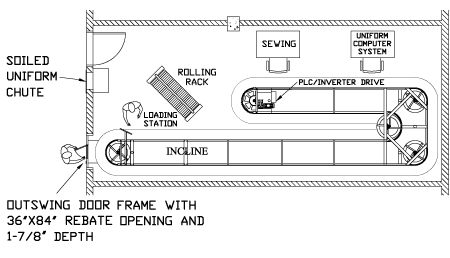

Top View:

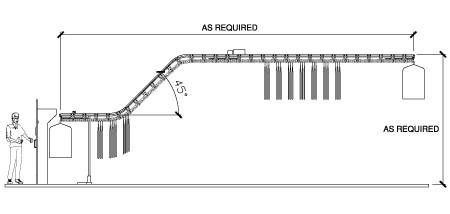

Side View:

Access Door:

Drive and Chain Options:

StrongBag Standard 20x28x4 PCSB205961IMP StrongLocker 36 Inch PCSL365961IMP StrongBag Basic 20x28x4 PCSB205909IMP Conveyor Bag 22×31 PCCB222809IMP Hanging Locker 22 x 44 PCHL442809IMP Hotel Bag 22×48 PCHB483

Product Gallery

Let SRS Auto Uniform Conveyor S-700 provide the solutions for all your uniform department requirements!

Our team of engineers can find the

solutions that is right for you.